Freight Wagon Information

Some

basic information about goods wagons

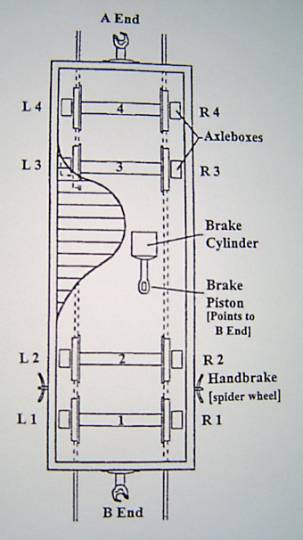

Q 1 - How do you tell the ‘A’ end from the ‘B’ end?

When modelling or photographing wagons,

it is a good idea to know which end of a wagon is what! As the drawing

indicates the relationship of equipment is basically the same on all

rollingstock.

On both 4 Wheel and bogie

wagons, the direction of the brake cylinder piston always points to the

handbrake wheel, which is always fitted on or towards the ‘B’ end of a wagon.

The brake equipment is laid

out underneath the wagon, along the centerline on 4 Wheel wagons and off to the

right-hand side on bogie vehicles.

On bogie hopper wagons, all

brake equipment is arranged on the ‘B’ end platform. The handbrake is usually

mounted on that end too, but exceptions do exist.

The latest bogie wagons, such

as well wagons and multi-pack vehicles have bogie mounted brake equipment. They

only have a

Multi-compartment air reservoir/triple valve attached to the chassis.

Q 2 – How does the air brake

system work?

The basic

principal of the air brake system is that air pressure is used to keep the

brakes released. Any reduction of pressure in the system will cause the brakes

to apply. The driver applying the brakes from the locomotive can make this

reduction, a burst train brake hose or any other event that causes the

separation of brake hoses, derailment etc.

Each wagon is fitted with a:

- ‘Brake

Pipe’ which travels the full length of the vehicle At each end there is a

flexible brake hose and shut-off tap.

-

‘Auxiliary

Reservoir’, which stores air under pressure

-

‘Triple

Valve’, this is the brain of the air brake system. It perform 3 processes

(CAR),

o

Charges the auxiliary reservoir from the BP,

o

Applies the brakes by directing air from the aux reservoir to the BC and,

o

Releases the brakes by directing the air in the BC via a grade control

valve or choke to atmosphere.

-

‘Brake

Cylinder’, which turns air pressure force, via a piston into mechanical

movement of the brake shoes thru brake rigging.

-

and a

‘Handbrake’, that is used to secure a wagon for extended periods.

Basic Automatic Train Brake Operation –

Once all

the brake hoses along the train are coupled together, and to the locomotive,

the driver places his brake handle into the release position and train brake

pipe is charged from the locomotive’s ‘Main Reservoir’ (MR) to full brake pipe

pressure (BPP). The brakes release as the BP is fully charges.

The

Triple Valve (TV) is basically a pressurized, horizontal cylinder with a piston

inside. On the left-hand side of the piston there is brake pipe pressure (BPP),

on the right-hand side there is auxiliary reservoir pressure. The TV allows the

charging of the auxiliary reservoir from the brake pipe when the BP is being

charged. This is done by the inrush of brake pipe pressure on the left being

greater than aux reservoir pressure on the right, thus moving the piston to the

right, this opens a port to the reservoir and charges it to full BPP. When both

pressures are at full BPP, they are termed ‘equalized’ and the piston rests in

mid position.

When the

driver moves his brake handle to apply the brakes, BPP escapes to atmosphere

and the train BPP is reduced. The TV piston slides to the left as the auxiliary

pressure becomes greater than BPP. This movement of the piston opens a port,

which then allows auxiliary reservoir pressure to flow into the brake cylinder.

This pushes out the piston inside the BC and forces the brake shoes against the

tire of the wheel. As the pressure inside the auxiliary reservoir drops, the

piston inside the TV returns to the middle as both pressures equalize, this in

turn closes the port to the BC.

The

driver can make a further reduction in BPP if needed, and the process will

repeat again.

When the

driver moves his brake handle to the release position, air again flows into the

BP, and inside the TV, the BP now being greater than auxiliary reservoir

pressure, slides the piston to the right. This opens a port to allow BP to flow

into the aux reservoir to recharge it. Another port is opened which allows the

air in the BC to escape via grade control valve or choke to atmosphere to

release the brakes.

Q 3 – How

is brake equipment laid out on different types of vehicles?

The short answer is that all vehicles had equipment

laid out differently!

However, there are common versions of brake layout

design.

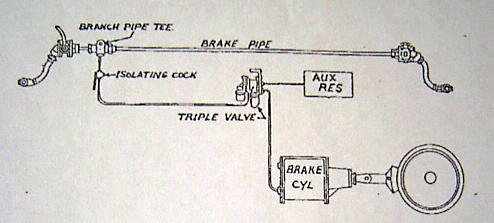

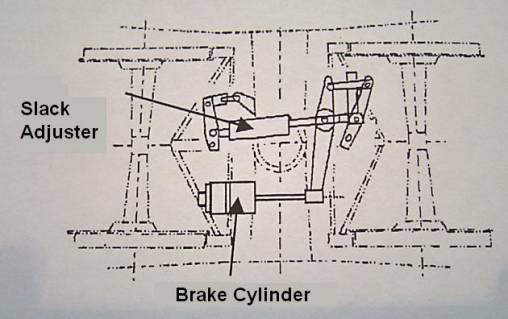

This drawing shows the most

basic form of air brake design used on NSW rollingstock. The principal design

was used on both 4 Wheelers and early (till mid-1950’s) bogie wagons. It is

suitable for vehicles that weigh up to 70t gross or run up to 65 km/h. The

drawing does not show the typical connection between the brake cylinder piston

and the brake shoe. This is done by a system of levers and rodding.

This drawing shows the most

basic form of air brake design used on NSW rollingstock. The principal design

was used on both 4 Wheelers and early (till mid-1950’s) bogie wagons. It is

suitable for vehicles that weigh up to 70t gross or run up to 65 km/h. The

drawing does not show the typical connection between the brake cylinder piston

and the brake shoe. This is done by a system of levers and rodding.

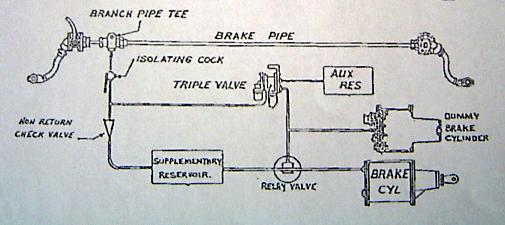

The next drawing shows how

the basic system was improved as trains became heavier and longer. The main

addition is the supplementary reservoir; it supplies a larger volume of air to

apply the brakes. It is used on vehicles that weigh over 75t gross and operate

up to 80 km/h

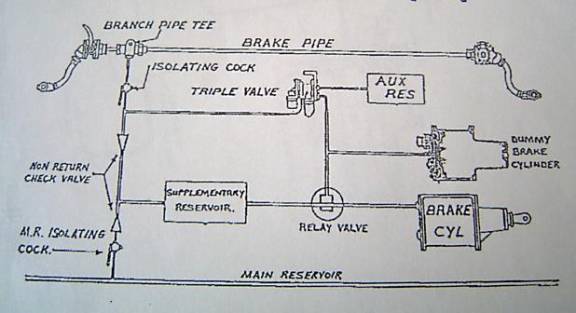

This design, introduced the

use of main reservoir air from the locomotive to assist in recharging the

supplementary reservoir on the vehicle. These wagons are fitted with a brake

hose as well as main reservoir hoses on the wagon headstock.

This design, introduced the

use of main reservoir air from the locomotive to assist in recharging the

supplementary reservoir on the vehicle. These wagons are fitted with a brake

hose as well as main reservoir hoses on the wagon headstock.

Air from the supplementary

reservoir is also used for other pneumatic equipment such as bottom discharge

door/roof hatch opening systems, where fitted. This design is used on wagons

with a maximum speed of 115 km/h.

The next

‘big leap’ in air brake design was the use of bogies with the brake equipment

mounted in them. In Australia, it has been used from 1995 on newly built long

container wagons and other body types that do not allow ‘traditional’ designs

to be used, such a multi-pack well wagons.

All air

delivery to the brake cylinder is via flexible hoses to each bogie.

Q 4 –

What is Grade Control?

Q 5 –

What is Load Compensation?

This equipment compensates for the weight of

the payload on a wagon. When a wagon is running empty, the amount of braking

force needed to slow the wagon is less than that is required when the wagon is

running around loaded. The compensator reduces the air pressure that enters the

BC when the wagon is empty and supplies normal pressure when the wagon is

loaded.

This equipment compensates for the weight of

the payload on a wagon. When a wagon is running empty, the amount of braking

force needed to slow the wagon is less than that is required when the wagon is

running around loaded. The compensator reduces the air pressure that enters the

BC when the wagon is empty and supplies normal pressure when the wagon is

loaded.

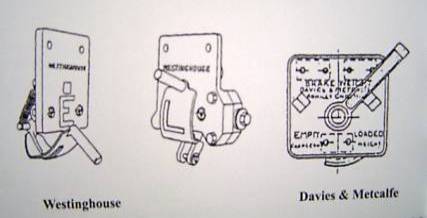

The Load compensator is changed manually, as shown

by the two types in the picture.

Most modern wagons are changed automatically using a

pressure switch mounted on the body or on the bogie bolster. The switch is

activated when it strikes the bogie side frame as the body/bolster lowers when

the wagon is loaded. Wagons fitted with Load Compensation equipment have a

square on the body side or codeboards on each side.

Automatic Load Compensation equipped vehicles have ‘ALC’ marked on the wagon codeboards.